Product Overview

IVEK Liquid Metering & Dispensing Systems have Three Fundamental Components:

Controller Modules

IVEK Corporation designs and manufactures its own dedicated electronics for the product line. The electronics are specifically designed to maximize fluidic performance. Forward and reverse fluid movement in addition to linear adjustable rate control, volume select, prime and dispense modes and drawback, for shearing viscous materials, are a partial list of the control options available.

The Controller Module can also include an operator interface panel to set parameters and signal alarms. Multiple channels, PLC interfacing, RS-232 communication, alarm systems and cycle outputs as well as custom options are configured, as the application requires. Stainless Steel, NEMA 4X panel mount and custom OEM enclosures are available. CE marking upon request.

There are two main types of controller modes as follows:

I. DISPENSING: Measured additions of fluid are displaced upon command. Dispensing applications are described as a volume per fill (ex. 0.5ml/package) Examples include:

- Bottle/vial filling

- Silicone Dispensing for Syringe Lubrication

- Blister Packs

- Many More

II. METERING: Continuous additions of liquid over time. Metering applications are described as a flow rate (ex.: ml/min). Examples include:

- Flavor Additions in Continuos Food Processing

- pH Control for Waste Water Treatment

- Electroplating Bath Replenishment

- Many More

Motor Base/Actuator Modules

The Motor/Base or Actuator Module drives the Pump Module. There are two varieties that correspond to the Pump Module types. The Motor/Base or Actuator Module drives the piston in a linear direction for the intake and discharge functions. Rotary motion is used for the valving function.

Motor/base or actuators available include the following:

Megaspense®; Motor Base (rotary system)

- Used for Larger Dispenses

- Different Motor Sizes Available for Various Fluid Viscosities

- Dispense volumes up to 15ml per stroke

Heavy Duty Motor Base (rotary system)

- Used for Larger Dispenses

- Different Motor Sizes Available for Various Fluid Viscosities

- Dispense volumes up to 1886µl per stroke

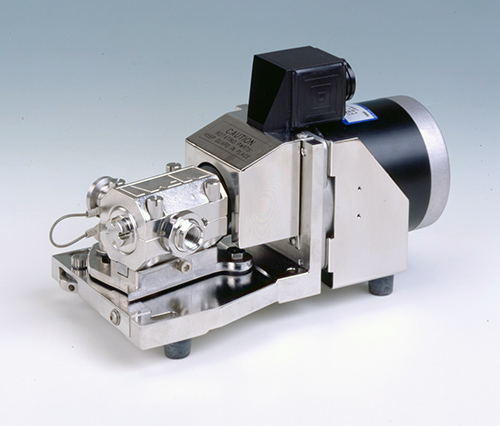

AP Motor Base (rotary system)

- Auto Prime Allows User to Easily Return to a Pre-Calibrated Setting After Priming/Cleaning

- Used for Smaller Dispenses

- Dispense volumes up to 109µl per stroke

DC Brushless (rotary system)

- Used for Larger Dispenses that Require Speed

- Dedicated to Digispense 10 Controller

- Dispense volumes up to 109µl per stroke

20 or 40-Pitch Actuators (linear system)

- Stepping Motor and Lead Screw Combo

- Used With Our Smaller Piston/Cylinder Sets

- 20P Actuator: Dispense volumes up to 2000µl per stroke

- 40P Actuator: Dispense volumes up to 200µl per stroke

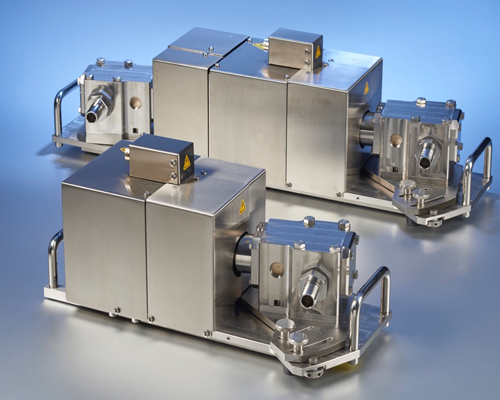

Multiplex Actuator

- Can Operate Up to 12 Pumps Simultaneously

- Piston/Cylinder is Driven by Both a linear and Rotary Motion

- LF: Dispense volumes up to 5000µl per stroke

- SF: Dispense volumes up to 400µl per stroke

Pump Modules

The IVEK pump module incorporates a ceramic piston/valve/cylinder set with housing. The housing for IVEK’s piston/valve/cylinder sets are typically comprised of 316 Stainless Steel and Tefzel. Custom materials can be used and are available upon request. The piston/valve/cylinder set is sealed by the fit of the piston into the cylinder. IVEK pump modules are positive displacement mechanisms that do not contain external valves and can run for hundreds of millions of cycles without measurable wear.

There are three types of pump modules: Rotary, Linear and Multiplex which are used for different applications depending upon the customer’s fluidic needs. These pump modules function differently however, they share the same basic features that result in a low maintenance pump module:

- Mated, serialized piston/valve/cylinder sets

- Tight clearance – 2.3-5.3 microns

- Minimal Friction

- Low fluid shear

- Withstand routine autoclaving and sterilization procedures

- Chemically inert – most acids, alkalines or solvents do not affect the ceramics

- Extremely hard – resist abrasion and wear

- No external seals needed due to tight clearance of piston/cylinder

- Titanium end cap press fit onto piston - eliminates adhesive contamination problems

- Low maintenance

- Flushing gland available to help eliminate binding issues with certain fluids